In production, accuracy is of first importance. Micro laser welding technologies provide a sophisticated technique for combining tiny, delicate components, therefore transforming sectors. This high-precision welding method produces extremely fine, clean welds in complex shapes using targeted lasers. Micro laser welding equipment offers unparalleled accuracy for sectors needing strict tolerances and low heat effect on materials as technology develops. This paper explores the features and advantages of these specific systems.

Understanding the Basics of Micro Laser Welding Systems

Operating by concentrating a high-intensity laser beam onto a workpiece, a micro laser welding system produces a precise and localized melt that fuses materials together. Micro laser welding reduces the total heat-affected zone by using focussed energy, unlike conventional welding techniques, which call for great heat and big instruments. This precision welding technique is perfect for small-scale components, especially in sectors including electronics, medical devices, and jewelry, where exquisite detailing and little heat effect are vital.

Applications of Micro Laser Welding Equipment

"Micro laser welding equipment" is flexible enough for a great spectrum of uses. It is used in the electronics sector to weld tiny, sensitive components such as microchips, therefore guaranteeing less thermal distortion and damage. Because micro laser welding can combine materials like titanium, which is often used in implants, medical device makers also gain from its accuracy and purity. Jewelers also use this technology to weld tiny pieces with complex designs, therefore enhancing general quality and appearance.

Advantages of Using Micro Laser Welding Systems

Micro laser welding systems offer one of their key benefits in being able to produce precise, small welds not possible with conventional techniques. Industries needing small parts to be linked without damaging adjacent materials depend on this great degree of accuracy. Furthermore, while laser welding is a non-contact technique, it removes the mechanical stress and contamination issues associated with conventional techniques as soldering or brazing. Stronger and more consistent welds with little post-weld cleanup follow from this.

Micro Laser Welding Systems and Material Compatibility

Furthermore, its capacity to toil with many materials is clear proof of micro laser welding systems' adaptability. Laser welding explains a wide scope of welding requirements, from metals like stainless steel, gold, or aluminum to more specialist materials like ceramics or polymers. The exact fusion made possible by the laser's precision control of its energy guarantees that the qualities of the material are maintained by avoiding distortion. Micro laser welding equipment is useful in sectors with different material requirements since it allows great flexibility.

Speed and Efficiency in Micro Laser Welding

Micro laser welding equipment also provides speed and efficiency, which are important advantages. The laser beam's fast heating and cooling cycles allow precise and quick welding. This can substantially save production time and boost throughput, particularly in sectors where mass manufacturing of small components depends on. Automating the welding process helps producers reach high-quality products without much time or effort, improving production.

Maintaining Micro Laser Welding Equipment for Longevity

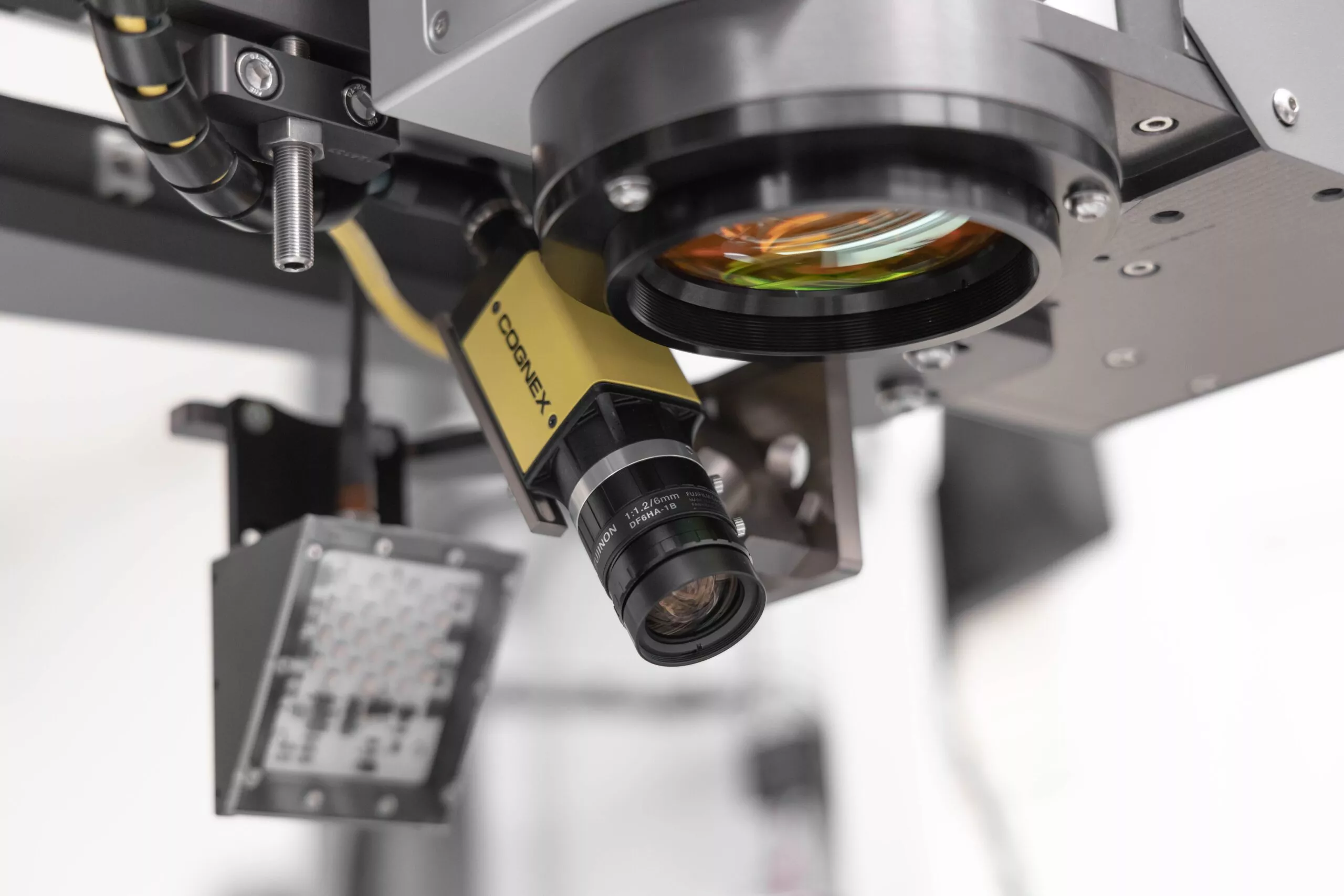

The excellent performance of micro laser welding systems depends on proper maintenance. Cleaning the lenses, verifying the laser is correctly calibrated, and looking for any equipment wear or damage are part of regular maintenance. Any company should invest in these systems as, with correct maintenance, they may offer years of dependable operation. Maintaining ideal condition of the equipment guarantees that the welding operation is accurate, effective, and defect-free.

Conclusion

Finally, micro laser welding systems and equipment are perfect for sectors that demand delicate and small-scale welding since they offer an unmatched degree of accuracy and efficiency. Visiting disentec.com provides access to the newest in laser welding technology for people who value premium, dependable tools. Micro laser welding is still a great help in many sectors since it may provide great accuracy and lower thermal impact.

To more deeply study us, visit our site.

Laser marking integration systems

Comments on “The Power of Micro Laser Welding Systems and Equipment in Precision”